In a world grappling with environmental challenges, forward-thinking architects and engineers are increasingly leaning towards more sustainable solutions. While steel and concrete have long dominated the construction industry, bamboo is now stepping into the limelight as a compelling alternative. Thanks to its potent mix of strength, flexibility, and eco-friendliness, bamboo is fast becoming the go-to material for those keen on pushing the boundaries of sustainable architecture.

Bridging this transformative moment in sustainable design is the timely arrival of the “Bamboo Structures” eBook series, which this article is based on. Acting as a touchstone in the field, the first volume focuses on the structural design process behind the Luum Temple—a masterclass in bamboo engineering. The guide serves as more than just a theoretical text; it is a comprehensive manual teeming with real-world insights, cutting-edge research, and practical expertise.

The use of bamboo as a structural material is far from a new phenomenon; it has a rich history that stretches back thousands of years. Despite its ancient roots, much of this traditional knowledge has been underestimated as the modern construction sector became overly focused on mineral-based materials. Today, however, bamboo is experiencing a global resurgence, bringing to light a harmonious blend of ancient wisdom with modern engineering. This fusion not only offers new avenues for sustainable architecture but also feels like a long-awaited, inevitable evolution of the construction industry.

The Luum Temple: An Icon of Sustainable Design

Nestled in the lush landscapes of Tulum, Mexico, the Luum Temple is more than just an eye-catching architectural marvel; it’s a pioneering example of what happens when traditional wisdom meets modern engineering. Designed to stand against 250 km/h hurricane winds and significant seismic forces, this structure embodies the compelling possibilities that arise when we harness bamboo’s unique properties as a structural material.

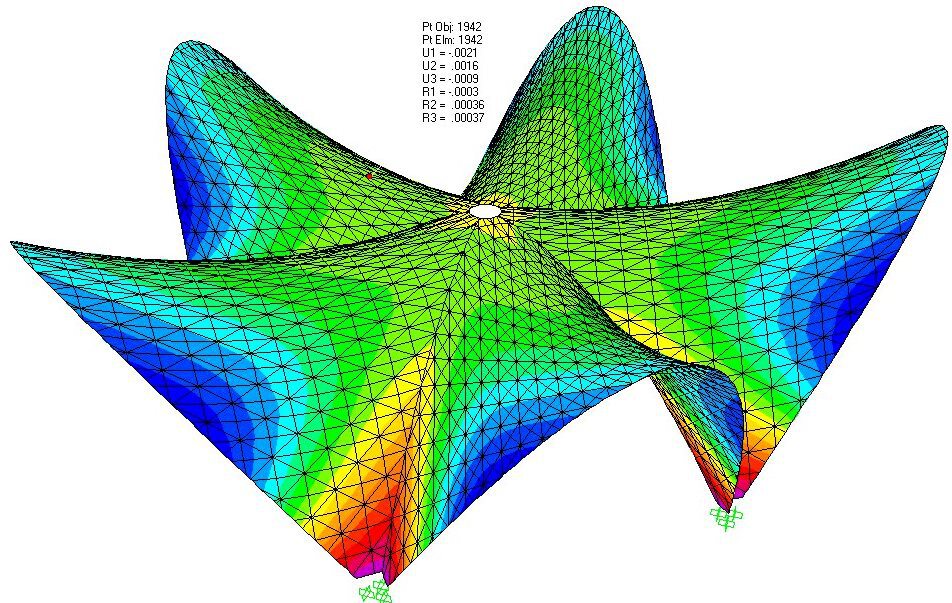

The architectural vision was conceptualized by the CO-LAB Design Office, brought to life by Architectura Mixta, and inspired by the iconic work of legendary architect Felix Candela. The engineering was led by Esteban Morales, who describes the structural system as five intersecting hyperbolic paraboloids made of bamboo arches and split bamboo beams.

Bamboo’s tensile strength-to-weight ratio often surpasses that of steel, making it not just strong but also lightweight. Flexibility is another advantage: especially when used in split form, bamboo enables architects to craft organic, flowing shapes that defy traditional geometrical constraints, facilitating the adoption of innovative structural approaches that rely on shape stiffness and biomimicry. Bamboo’s rapid growth and ability to sequester carbon also position it as an environmentally superior alternative to traditional construction materials, including timber.

On the other hand, working with bamboo also requires special care in certain aspects. Due to its lightweight nature, particular attention must be paid to foundations, cross-bracing and structural stiffness, which are essential to counterbalance its vulnerability to wind forces. Although bamboo’s low shear strength presents a challenge, an adequate comprehension of its properties allows for creative systems to compensate for this, and a critical focus on treatment is also non-negotiable. The material can also be prone to insect attacks and has a limited lifespan, making it important to include proactive ‘preservation by design’ approaches as an integral part of any bamboo-based construction.

The Engineering Process

A defining feature of the Luum Temple project was its successful integration of up-to-date bamboo engineering concepts with a timeless architectural framework. Rather than merely following standard procedures, the engineering team ventured into new territory by developing custom methods, all while adhering to internationally recognized standards. This inventive approach adeptly navigated through Mexico’s intricate regulatory framework surrounding bamboo construction and also set a solid precedent for future bamboo projects.

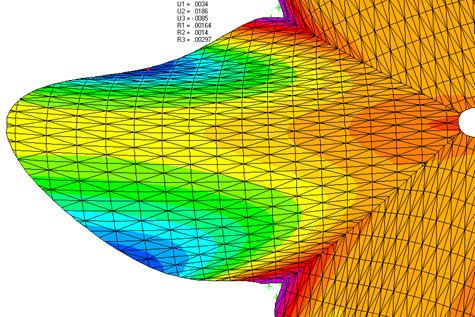

The technical workflow of the project was facilitated by a robust software toolkit. The structural design process started with AutoCAD 3D, where the structure’s geometry was modeled and compatibilized for the next steps. Following this, structural analysis was carried out using specialized structural analysis software SAP2000 v.14.

The structure was divided into three main element types to orient the design process:

- Arches, spanning in the edges of the structure and radially from the center;

- Joists, spanning in layers and connecting the main arches over several layers;

- Roof diaphragm, conformed by the rigid surface resulting from several layers of joist triangulation and split weaving below the roof.

As the project is located in a region prone to hurricane winds and seismic activities, the engineering strategy emphasized shape stiffness, triangulation, and a robust diaphragm. These elements were specifically selected to offset lateral forces that could compromise the structure. Consequently, each component in the structure was interconnected and designed to function cohesively, ensuring resilience against some of nature’s most extreme forces.

In terms of load magnitudes, considerable seismic loads and 250km/h hurricane wind loads governed the design. These were combined with dead loads (weight of the structure and roofing) and live loads to obtain the design internal forces for each element of the structure. For this, the allowable stress method was employed, complying with the most adequate approach for structural bamboo design. The loads were then multiplied by the prescribed load coefficient for each of the required load combinations according to bamboo-specific structural codes. Finally, the maximum internal forces found in the most stressed arch, joist, and roof diaphragm elements were considered for the final design of the structural elements.

Equipped with structural insights, such as the internal forces acting in the structure for each load combination, the structural components were designed based on bamboo-specific building codes, such as the NSR-10 (Colombia) and the ISO 22156 (International). Specialized software like WoodWorks® Connections, SFS Timber Work, and APF Wood Joint were then employed for the design of the connecting elements between structural components.

At the uppermost part of the structure, the primary arches converge, interconnected by a central steel compression ring. This design feature ensures each arch tip converges towards a centralized point, reminiscent of a star’s radiating arms. Drawing a parallel to airplane wings, which flex and bounce to a certain extent during flight to prevent structural failure, bamboo structures adopt a similar engineering principle. To ensure the bamboo components can flex and adapt during adverse events like storms or earthquakes without fracturing, the central compression ring incorporates robust hinged connections, as illustrated in the subsequent images.

Unlock the Potential of Bamboo Structures

For those serious about pioneering the next wave of green construction and understanding the practical aspects of using bamboo as a structural material, the “Bamboo Structures” eBook series can be an essential guide. This recent publication dives deep into methodologies, design details, and example applications, serving as an invaluable resource for both novices and experts in the field. Developed based on the structural calculation methods used for the Luum Temple project, this first volume addresses a long-awaited resource gap, offering a clear lens into bamboo structural design for the wider audience.